Unmatched Durability

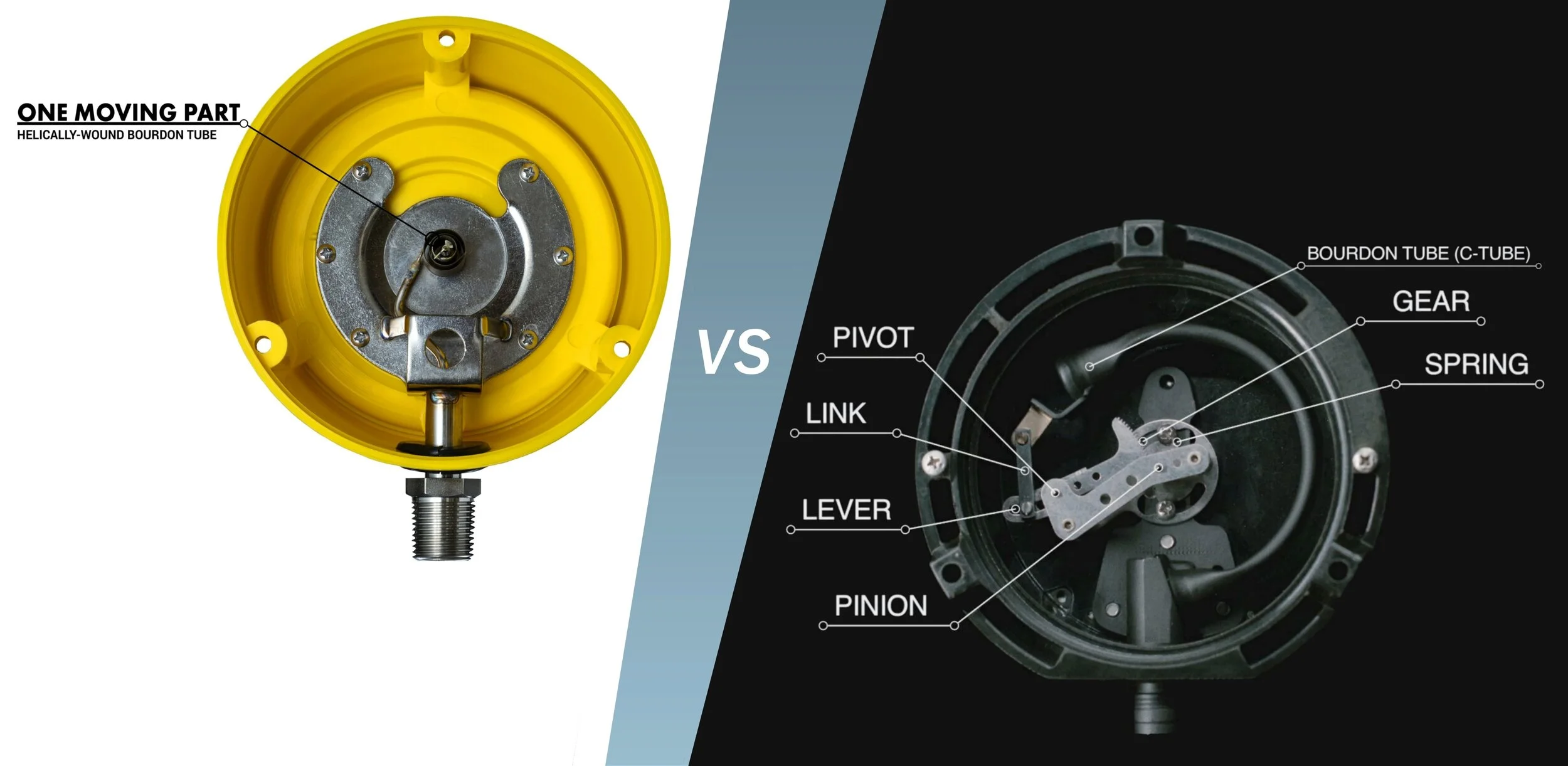

The difference is simple… There is only one moving part.

Perma-Cal® Direct Drive

Competitors C-Tube Design

One moving part

No Gears, No Linkages, No Springs

Helical Bourdon Tube attached directly to the pointer shaft

Multiple moving parts

Over time, movement-amplifying gears, linkages and springs can wear or break

Requires lubrication for proper functionality

No liquid fill

Internally dampened to reduce pointer flutter

No internal mechanical components requiring lubrication

Liquid filled

Liquid filled to reduce pointer flutter and for internal lubrication

Over time, liquid fill can leak or cause discoloration resulting in premature failure

Greater life equals lower costs

Fatigue life oftentimes of 1,000,000 cycles or more

Reduces maintenance costs and allows for extended recertification cycles

Shorter fatigue life

Fatigue life often only 20,000-30,000 cycles

Internal wear results in increased maintenance and shorter recertification cycles

Safety is prioritized

All gauges feature a Solid Front Case for greater protection

Low volume minimizes spillage if catastrophic failure occurs

Safety is optional

Optional solid front case increases risk of blowout in the front

High volume spills large amounts of process if catastrophic failure occurs

Proof Pressure above industry standard

Withstands over-pressure of 150% F.S.

Standard Proof Pressure

Withstands over-pressure of 125% F.S.

Reliable temperature performance

Inconel, Helical Bourdon Tube means that accuracy is 25% less affected by changes in temperature

Options available operating from -65°F up to 600°F Media

Uncertain temperature performance

Stainless Steel, C-Type Bourdon Tubes provide less consistent readings vs. Inconel

Standard operating temperature -40°F up to 212°F Media

Consistent, accurate diaphragm seal performance

Unique, low volume design requires 85% less fill fluid. This means accuracy is 50% less affected by temperature changes

Mini-Seal compatibility provides performance advantages and significant cost savings

Inconsistent diaphragm seal performance

High Volume C-Tube combined with a larger seal requires significantly more fill fluid

Increasing temperature leads to fill fluid expansion and inconsistent accuracy

Aerospace Quality | Military Trusted

Military and Aerospace Engineers recognize the performance advantages Direct Drive Design offers and demand it on critical applications

Commercial Standard Design

C-Tube design is widely used in standard commercial and military applications, but is very rarely seen in Aerospace