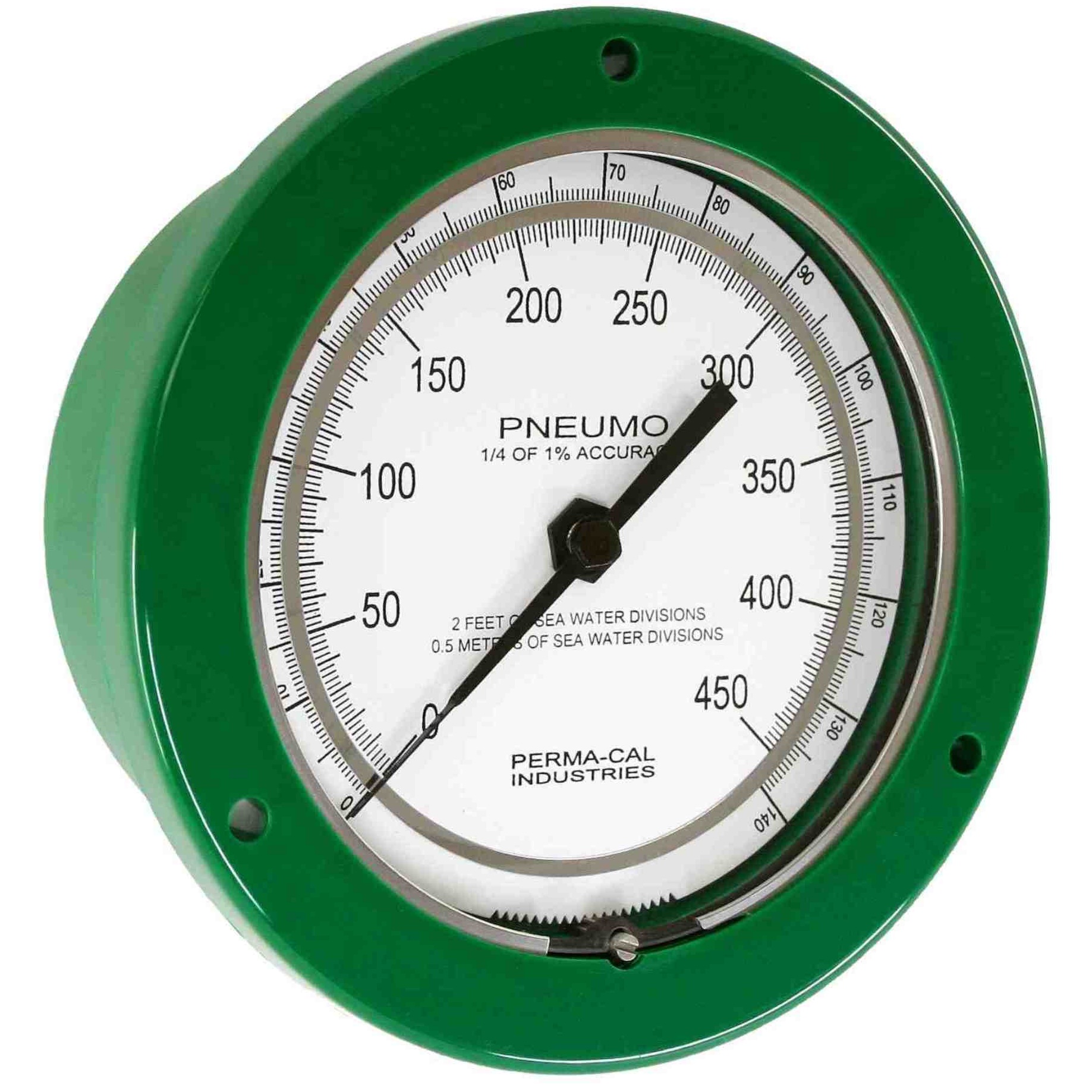

Pneumo Depth Gauges

IDEAL FOR SEA WATER DEPTH MEASUREMENT

Advantages

ONE MOVING PART

Unmatched vibration, pulsation and shock performance.

Helical Bourdon Tube = Gearless, Direct Drive = DURABILITY

No linkages, springs, gears, or liquid fill to wear, break or leak. Unique, internal pointer dampening reduces pointer flutter without the negative consequences of liquid fill.

TRAVEL READY

Survives the day to day transport and use of a commercial diving case.

Don’t sweat the accidental drop or rough seas. Direct Drive Design is inherently more durable in the areas of shock and vibration.

CORROSION RESISTANT

High quality materials ensure reliable performance year after year in a highly corrosive application. It’s no wonder we consistently receive gauges for re-certification which are over 20 years old.

USA PARTS, USA MADE, USA OWNED

Manufactured in Minden, NV using only American made parts. Manufacturing processes not completed in house are outsourced to support local small businesses.

TRUSTED ACCURACY

Accuracy is 25% less affected by temperature fluctuations.

Inconel Elastic Element = Low Coefficient of Thermal Expansion

Inconel in combination with a low internal volume means that the impact of temperature on accuracy is significantly less than competitors using a Stainless Steel Bourdon Tube.

U.S. NAVY TESTED

Direct Drive is demanded on critical applications.

Trusted to perform in the most extreme marine environments, our gauges are widely used by the US Navy.

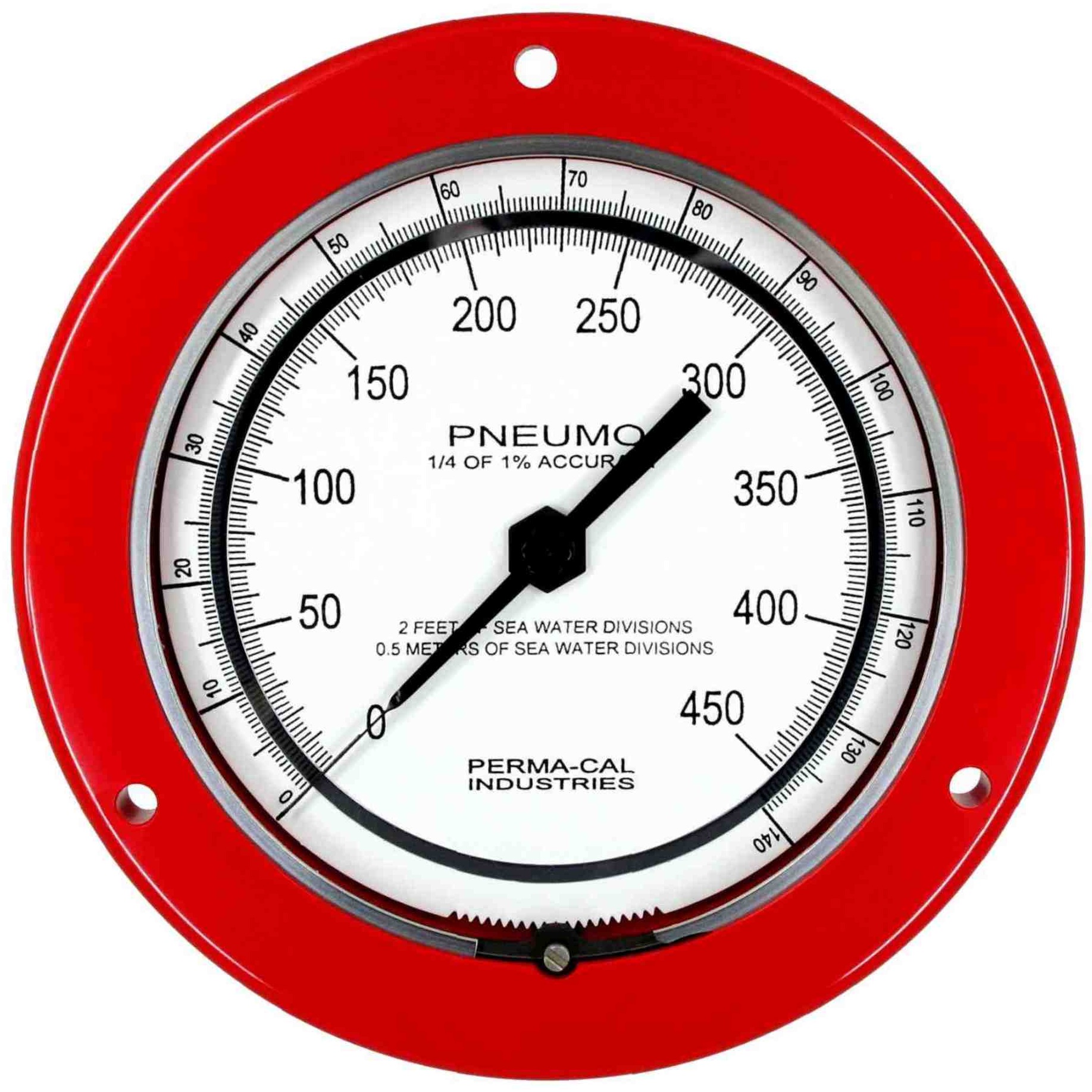

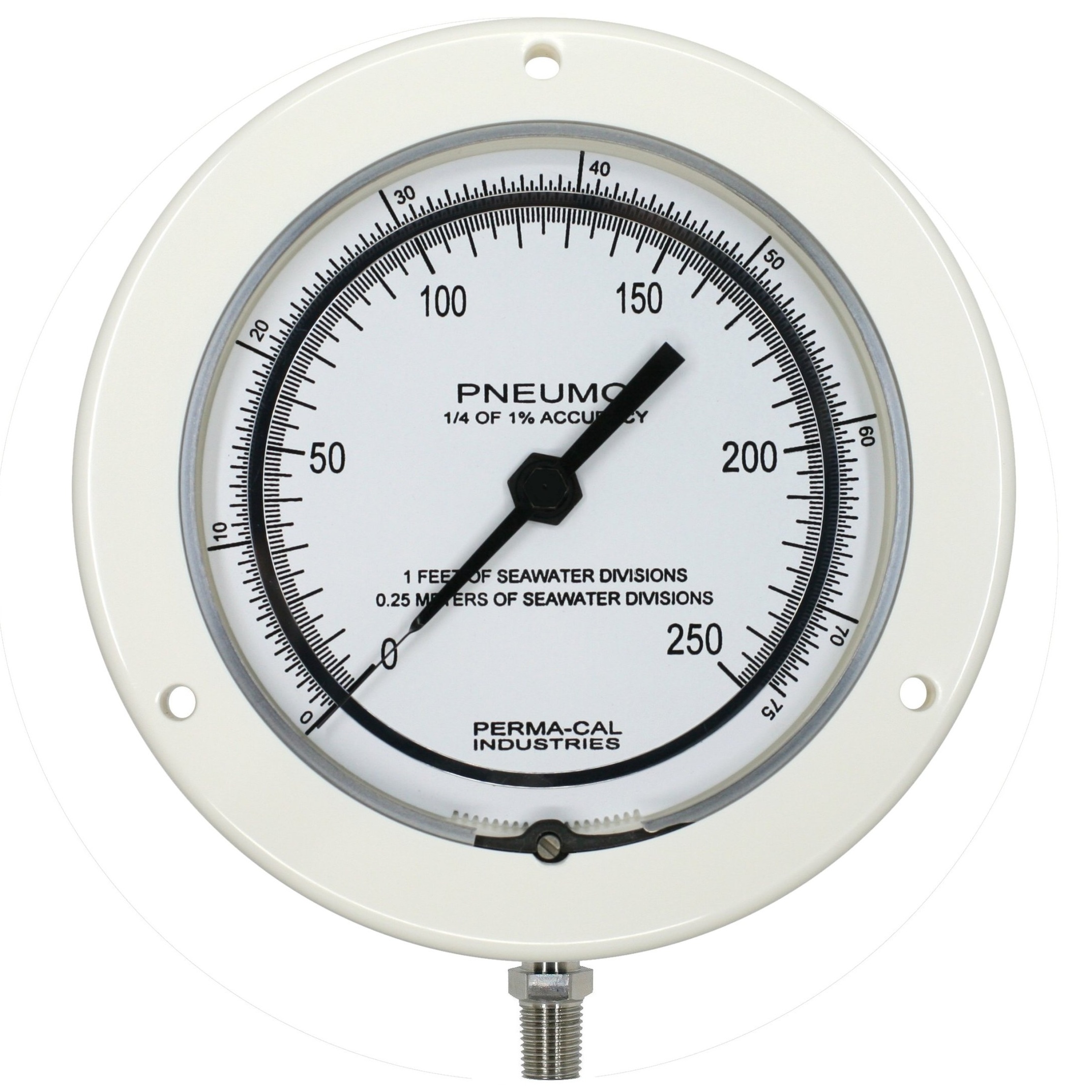

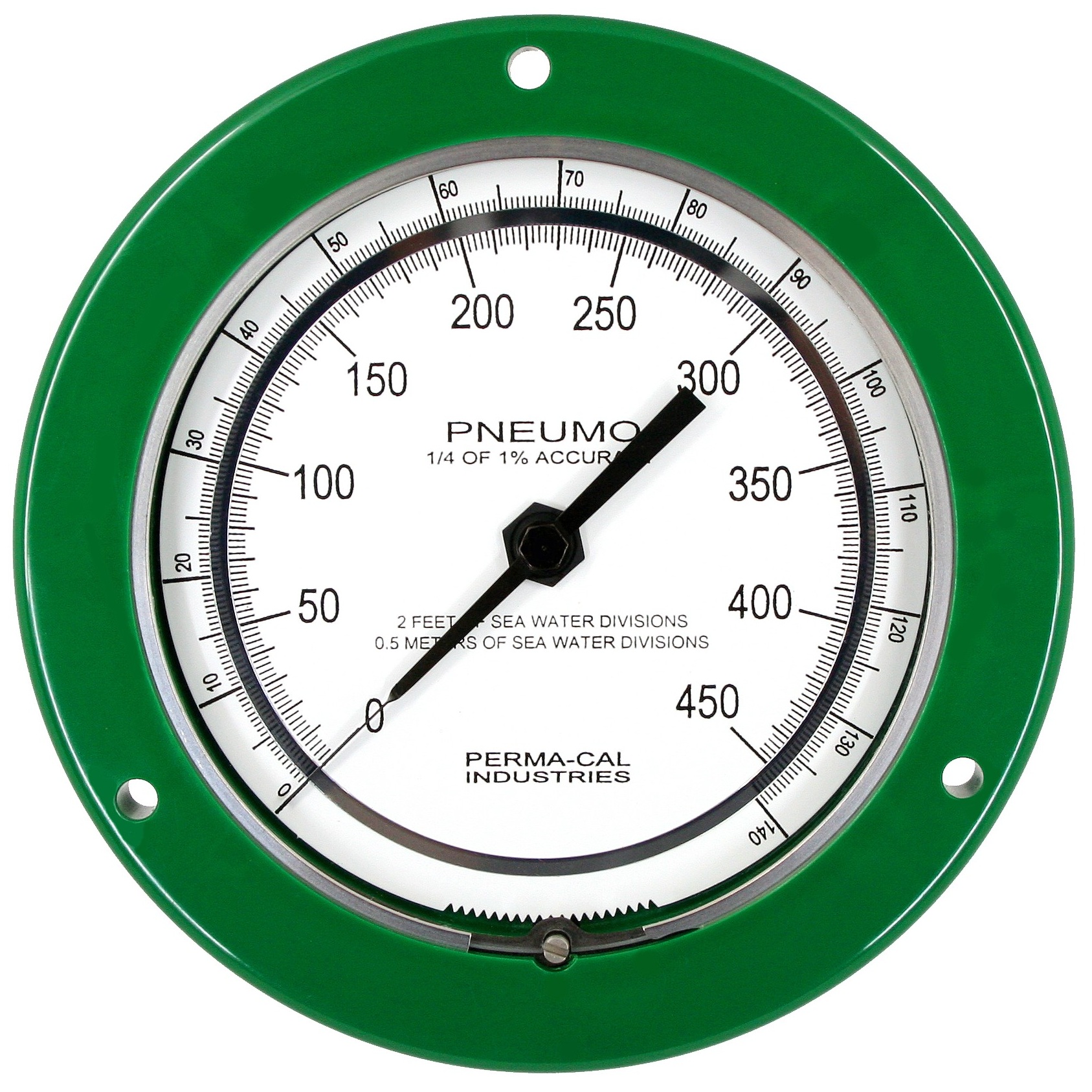

EASY COLOR CODING

Color code by diver. ABS plastic cases are available in a variety of standard colors: Black, Blue, Green, Red, White and Yellow.

LIFETIME LIMITED WARRANTY

Lifetime warranty that the Bourdon tube will not malfunction due to wear.

1 year from delivery or 18 months from date of manufacture against defects in materials and workmanship.

Pneumo Gauge Specs

TYPICAL APPLICATIONS

Ideal for use wherever accurate sea water depth measurement is required.

Commercial Diving

Submarines

Sea exploration equipment

Air control systems

Diving vessels and more...

ACCURACY

±0.25% of F.S. (Grade 3A)

For details see accuracy specs page

RANGE AVAILABLITY

70 to 3,500 FSW (or equivalent)

Single Scale: FSW

Dual Scale: MSW | FSW

Customization available (range, units, logo, etc.)

See dial availability chart for list of standard ranges

OPERATING TEMPERATURE

Media Temperature:

ABS: -65°F to 250°F

SS: -65°F to 600°F

Ambient Temperature:

ABS: -65°F to 190°F

SS: -65°F to 400°F

OTHER SPECIFICATIONS

Burst Pressure: 500% F.S. pressure or 25,000 psi

Proof Pressure (over-pressure w/o calibration shift):

150% of F.S. pressure

Internal pointer dampening (reduces pointer flutter)

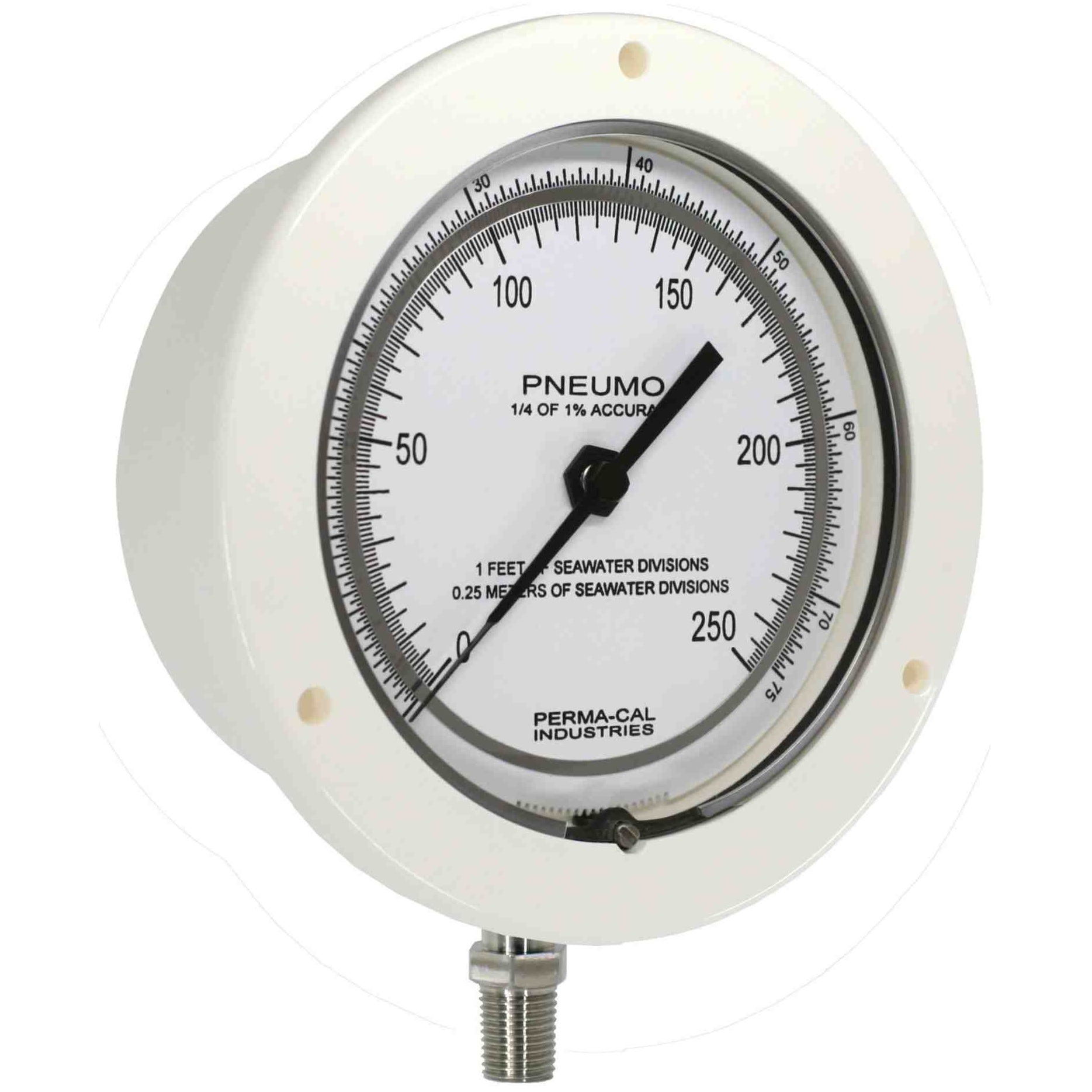

CASE CONFIGURATIONS

Materials:

ABS (acrylonitrile butadiene styrene)

Stainless Steel

Sizes, Types and Colors:

4.5", 6", 8.5" Dial

Front Flange, No Flange, Rear Flange, Turret Style

Black, Blue, Green, Red, White, Yellow

SS Case Finish: Powder Coated or Unpainted

Solid Front Case Design

QUALITY MATERIALS

Wetted Parts:

Inconel X-750

300-series SS

Silver Braze

Connection Material: 316 Stainless Steel

Window Construction:

Acrylic

Tempered Glass available

Dial Construction:

Stainless Steel Material, Powder Coated Finish

White Background, Black Markings, Black Pointer