Skydrol Gauges

CORROSION RESISTANT PRECISION PRESSURE GAUGES

Advantages

ONE MOVING PART

Unmatched vibration, pulsation and shock performance.

Helical Bourdon Tube = Gearless, Direct Drive = DURABILITY

No linkages, springs, gears, or liquid fill to wear, break or leak. Unique, internal pointer dampening reduces pointer flutter without the negative consequences of liquid fill.

OOPS! PROOF

Proof Pressure (over-pressure) of 150% F.S. exceeds industry standards.

Survives the day to day beatings of a rigorous hydraulic testing environment. Additionally, where vacuum can sometimes damage a C-tube gauge, Direct Drive is unaffected.

LIFETIME LIMITED WARRANTY

Lifetime warranty that the Bourdon tube will not malfunction due to wear.

1 year from delivery or 18 months from date of manufacture against defects in materials and workmanship.

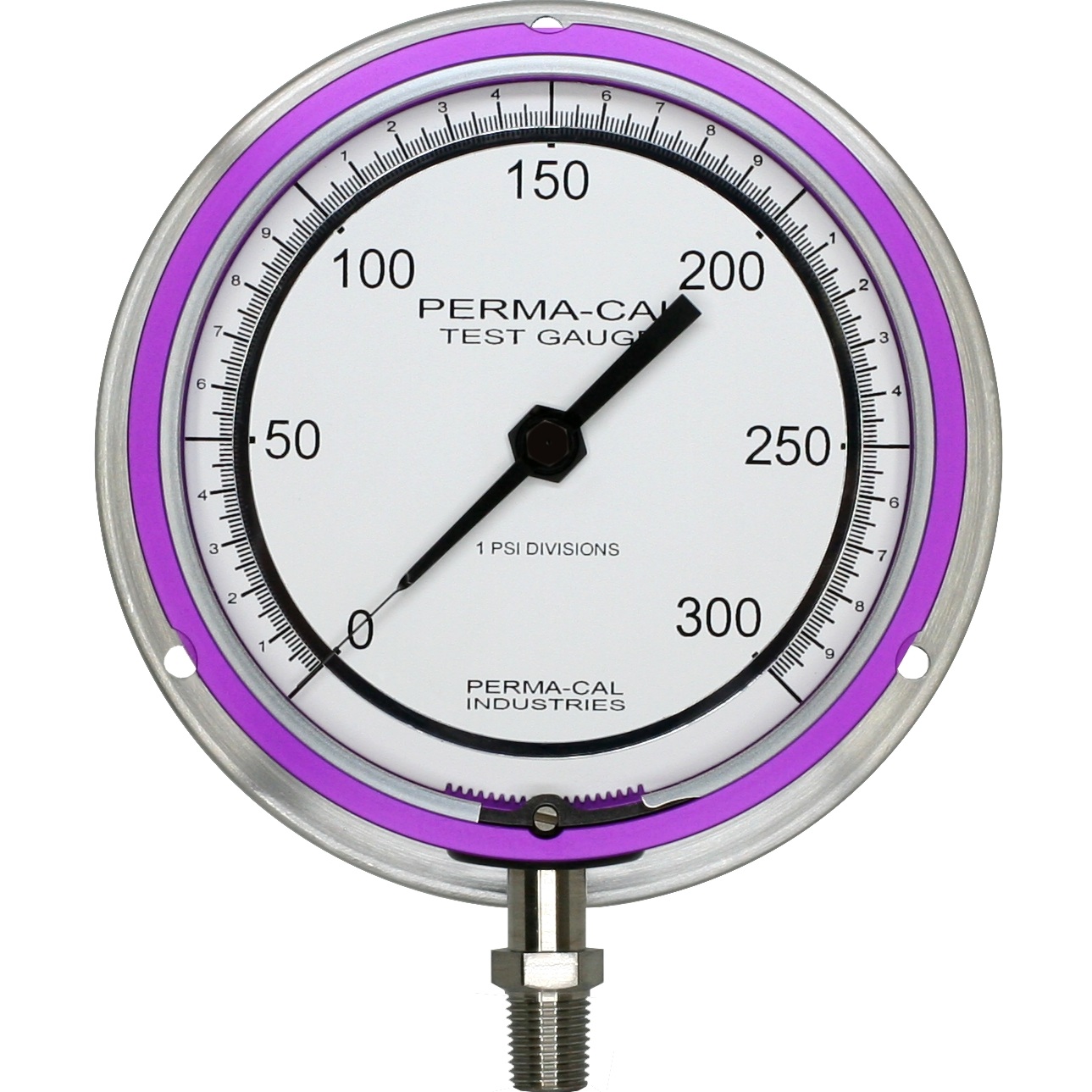

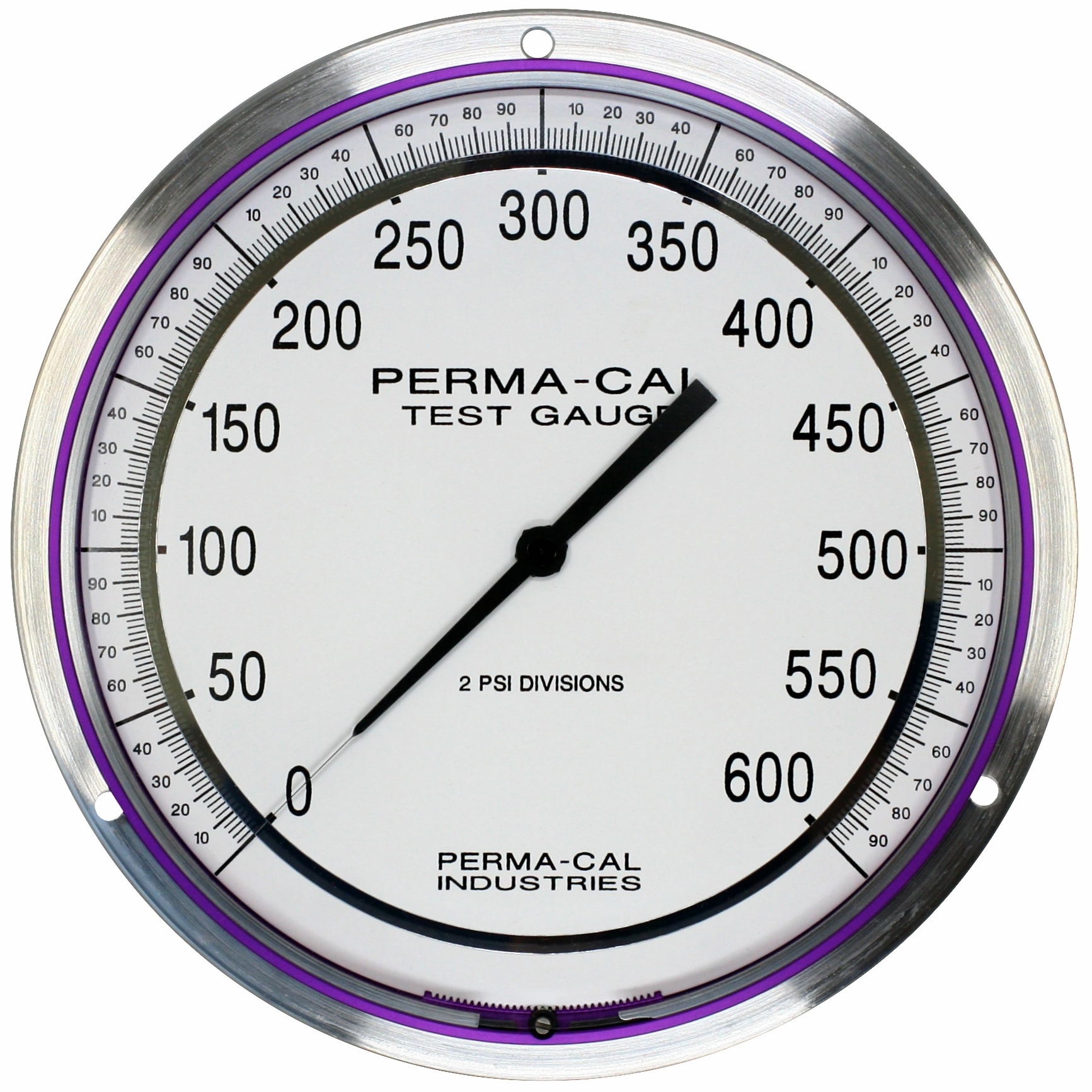

CLEARLY IDENTIFIES

SKYDROL

USE

Purple aluminum ring (Hard Anodize / Type 3, Class 2) clearly identifies Skydrol use without the risk of corrosion or discoloration.

AEROSPACE QUALITY | MILITARY TRUSTED

Direct Drive Design is demanded on critical applications. Military Grade MIL-S-901 shock tested case.

The same military grade Direct Drive technology used in our Aeropsace and Military designs, is used in our Skydrol solution.

The U.S. Military recognizes the durability advantages Direct Drive provides and requires it on their most demanding applications.

EXTREME CHEMICAL RESISTANCE

High quality materials provide extreme resistance to corrosive media.

USA PARTS, USA MADE, USA OWNED

Manufactured in Minden, NV using only American made parts. Manufacturing processes not completed in house are outsourced to support local small businesses.

Skydrol Gauge Specs

TYPICAL APPLICATIONS

Ideal for use in aerospace hydraulics testing facilities and fluid control manufacturing facilities where Skydrol is used.

Product is designed for highly corrosive chemicals and can be customized to designate usage other than Skydrol.

ACCURACY

±0.25% of F.S. (Grade 3A)

±0.5% of F.S. (Grade 2A)

±0.5% F.S. at M.S. / ±1.0% F.S

For details see accuracy specs page

RANGE AVAILABILITY

Vacuum - 15,000 psi (or equivalent)

Units: psi, bar, kPa, MPa, kg/cm², inHg, mmHg

Types: Single or Dual Scale, Vacuum and Compound

Customization available (range, units, logo, etc.)

See dial availability chart for list of standard ranges

OPERATING TEMPERATURE

Media Temperature: -65°F to 600°F

Ambient Temperature: -65°F to 400°F

OTHER SPECIFICATIONS

Burst Pressure: 500% F.S. pressure or 25,000 psi

Proof Pressure (over-pressure w/o calibration shift):

150% of F.S. for gauges ≤ 5,000 psi or equivalent

125% of F.S. for gauges > 5,000 psi or equivalent

Internal pointer dampening (reduces pointer flutter)

CASE CONFIGURATIONS

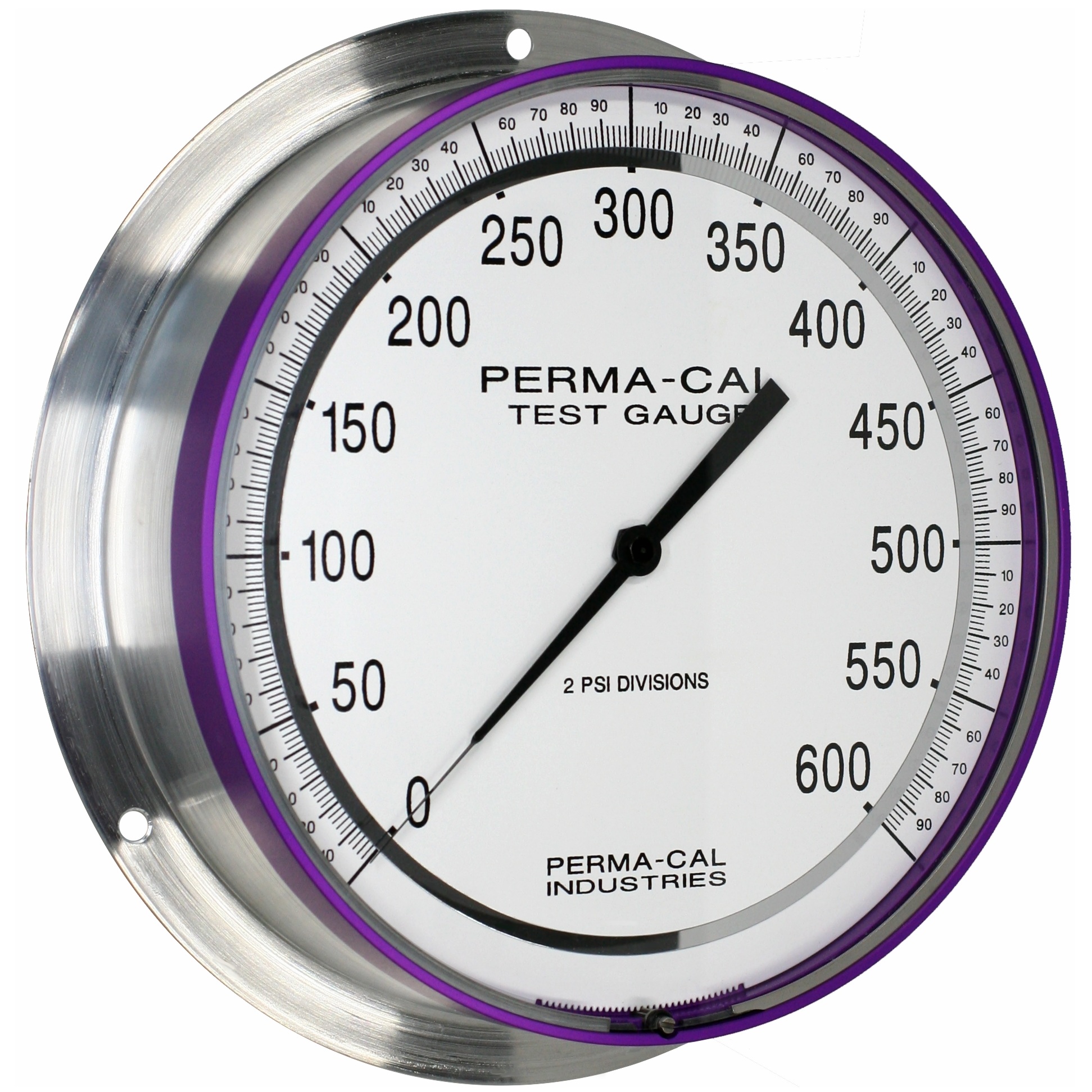

Materials:

Aluminum Case

Aluminum Ring (Purple Hard Anodize Type 3, Class 2)

Sizes, Types and Colors:

3.5", 4.5", 8.5"

Rear Flange

Unpainted Case, Purple Ring

Solid Front Case Design

Customization available (flange, colors, etc.) Contact the factory.

QUALITY MATERIALS

Wetted Parts:

Inconel X-750

300-series SS

Silver Braze (nickel braze available)

Connection Material:

316 SS standard (Monel available)

Window Construction: Tempered Glass

Dial Construction:

Stainless Steel Material, Powder Coated Finish

White Background, Black Markings, Black Pointer